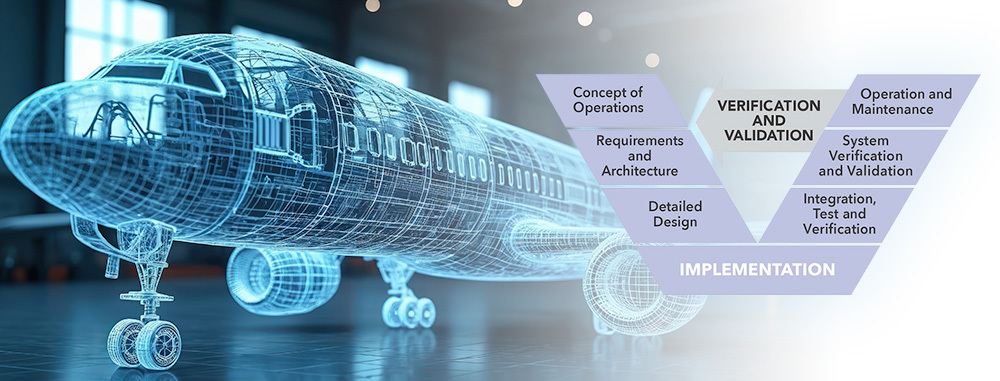

In today’s evolving engineering landscape, Model-Based Design (MBD) has emerged as a game-changing approach that accelerates development, enhances accuracy, and reduces costs. By leveraging digital modeling, simulation, and automated code generation, engineers can identify design flaws early, optimize performance, and streamline deployment. MBD is widely used across aerospace, defense, automotive, robotics, and embedded systems, ensuring efficiency in complex projects.

Aerospace and defense industries rely on MBD to perfect flight control systems, autonomous vehicles, hardware-in-the-loop testing, and cybersecurity for embedded systems. Tools like MATLAB/Simulink™ allow engineers to simulate aircraft dynamics, test mission-critical algorithms, and validate hardware before real-world implementation. With its ability to integrate physical and virtual components, MBD significantly reduces risk while improving system reliability.

Simulink is a powerful upper-level CASE (Computer-Aided Software Engineering) tool that streamlines MBD by enabling intuitive system modeling, rapid prototyping, real-time testing, and automated code generation. By integrating design, simulation, and verification, it minimizes development time and reduces costly errors, making it indispensable for industries many industries. UEI has advanced this approach by achieving 100% reuse of models, including code generation and hardware, from simulation to deployment, ensuring efficiency and reliability.

Beyond aerospace, MBD’s influence extends to automotive, where companies use it for self-driving technology development, and marine turbine engines, where engineers refine turbine efficiency. Our team here at UEI supports MBD applications with cutting-edge hardware that enables seamless model execution, from simulation to live deployment. As industries embrace MBD, its role in innovation, precision, and cost-effective engineering continues to expand.