Get in Touch

UEI Europe Office

+49 40 63698136

Email EU Sales

General

(508) 921-4600

Email Sales

Email Support

Click here for local offices and distributors.

LVDT/RVDT Tutorial Reference Guide

QUICK LINKS | ||

|  |  |

|  |  |

What is an LVDT/RVDT?

LVDT is an acronym for Linear Variable Differential Transformer. It measures absolute linear displacement.

RVDT is a Rotary Variable Differential Transformer. It measures absolute rotary angle.

Additional information to know about LVDT/RVDT:

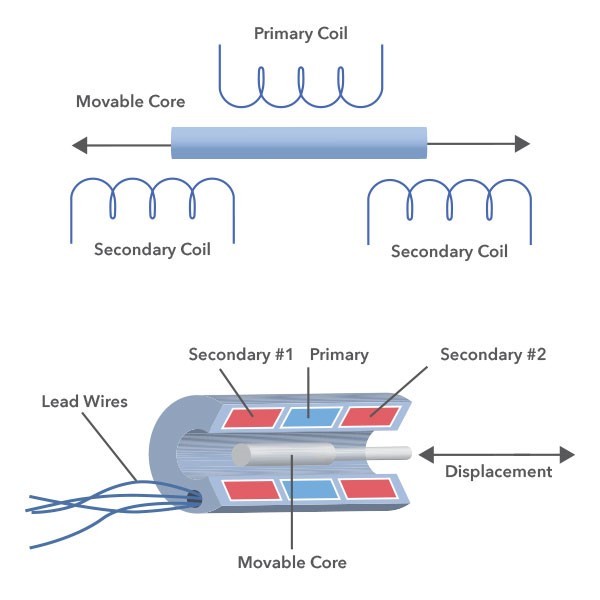

- Transformers normally require 3 parts: a primary coil, a secondary coil, and a core. The primary coil uses AC voltage to induce a current in the secondary coil. The core is required to efficiently transfer power from one side to the next.

- You might be asking, can air be a core? Sure! But you get less power transferred to the secondary coil because air is less magnetically permeable than normal core materials, like iron alloys.

- A VDT (Variable Differential Transformer) is a type of transformer where there are two secondary coils, and a movable core. If the core is moved one way, then one of the secondary coils gets power transferred more efficiently to it than the other secondary coil, and vice versa.

- In order to read the “position” of a VDT, you would simply need to take the ratio of secondary coil A to secondary coil B.

Overview

UEI manufactures a wide variety of analog and digital IO boards; including ones for Synchro/Resolvers, LVDTs, and RVDTs. Each board can supply the excitation voltage and measure the output wave forms of the transducer. They can also be used in simulation applications to simulate the output of the transducer.

Like all UEI IO Boards, the LVDT/RVDT IO Board offers operation in harsh environments and has been tested to last within:

- 5G Vibration

- 50G Shock

- -40 to 85 Degrees Celsius

- Altitudes up to 70,000 Feet

LVDT/RVDT allows you to monitor and control:

- Thrust lever on a jet

- Hydraulic positioning

- CNC mill positioning control

- ATM cash thickness measurement (it’s a legitimate thing, look it up)

- Turbine positioning

Anything that needs physical positioning measurement is a good candidate.

Absolute Analog Positioning in Harsh Environments

- An LVDT is used within hydraulic pistons to measure absolute displacement.

- RVDT is used on the thrust level of a jet to measure absolute rotary angle.

VDT System Types

Configurations of a VDT:

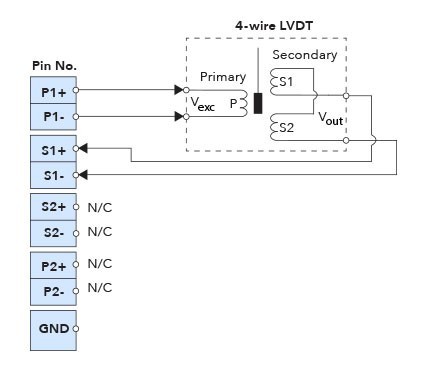

- 4-wire: 2 of which connect to the primaries, 1 connecting to secondary A, and 1 connecting to secondary B.

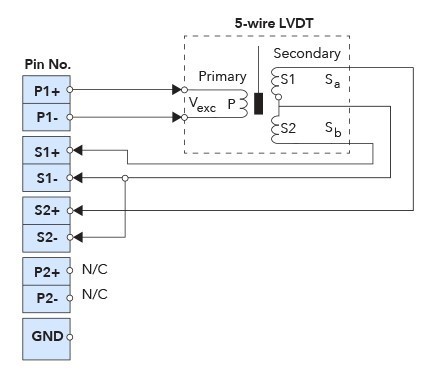

- 5-wire: 2 of which connect to the primaries, 1 connecting to secondary A, 1 connecting to secondary B, and 1 connecting to the common between A and B.

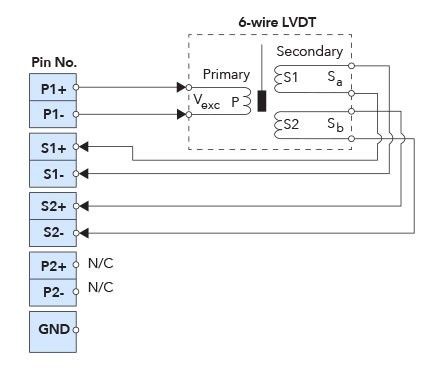

- 6-wire: 2 of which connect to the primaries, 2 connecting to secondary A, and 2 connecting to secondary B.

| Check out the list of figures and diagrams in the AI-254 user manual for additional information. |

VDT Excitation Types:

Internally Excited: With internally excited VDTs, your interfacing system needs to read in the AC voltage on the primaries and compare that to the secondary voltages.

Externally Excited: With externally excited VDTs, you need to provide an external excitation to the primaries and read it back on the secondaries.

What programs can you run with LVDT/RVDT boards?

- C

- C + +

- C#

- Simulink

- Python

We have designed our data acquisition hardware to be software flexible. That means you can use a variety of programming languages and programs with our UEI I/O boards. One particularly popular program used is National Instrument’s ‘LabVIEW’. We supply these samples so you can create a standard acquisition application in the shortest time possible. UEI supports a variety of acquisition modes (Buffered IO, Simple IO, Messaging IO, DMap IO) which can be accessed through the simple pull downs.

Our extensive collection of prebuilt examples and VIs make it easy to get up and running quickly. Our LabVIEW interface has the same API as our C API, which means that there are no islands of programmers at your facility. Your LabVIEW and C programming teams can exchange knowledge and experience seamlessly.

How to Activate Your Program

- First, start by plugging a board into a chassis.

- Now, power on the chassis hardware and open the LabVIEW example.

- If you go to Window> Show Block Diagram, you can see UEI VIs ready to go. In fact, there is a UEI tree which lists all the UEI VIs. Similarly, depending on the type of data you are wishing to acquire, you can use the session polymorphic VI pull down to configure different inputs or outputs.

- Run the LabVIEW example to begin communicating to the chassis, reading Synchro/Resolver position.

As you can see, there are simple drop downs which will allow you to configure your system to whatever specifications you would like; whether that be changing the data value you are recording or changing the method of acquiring such data.

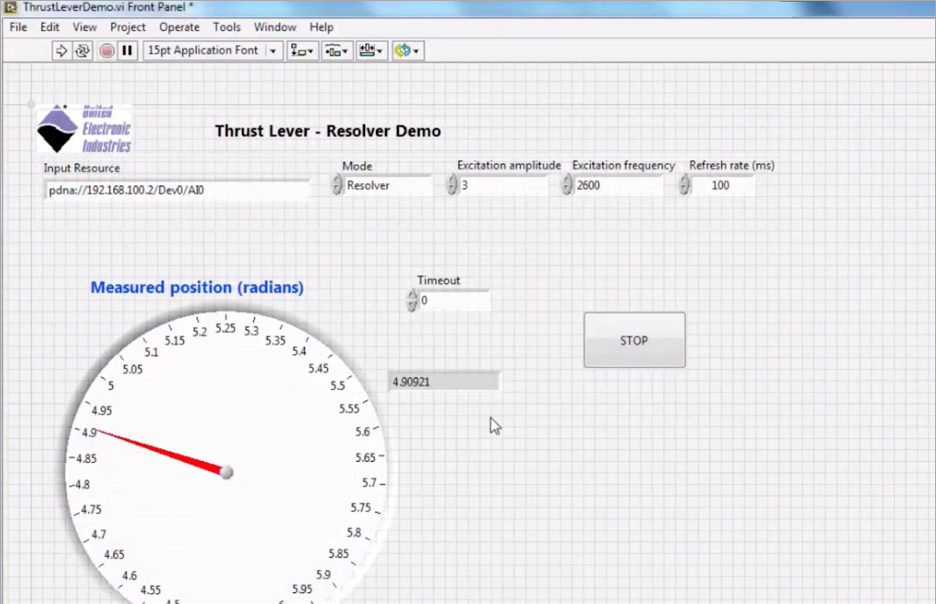

Here is a demo of a throttle system in which the position of the throttle is being measured by the resolver and relayed into a LabVIEW application.

The UEI LVDT/RVDT Reliability:

- Long lifespan due to a non-contact architecture

- Absolute positioning

- Theoretically infinitely precision positioning

The Physical I/O Board

Board | Input Range | Simulation/Excitation Range | ||

Voltage | Frequency | Voltage | Frequency | |

2-28Vrms | 100Hz-5kHz | 2-6.7Vrms in 4-wire and 6-wire mode 1-3.35Vrms in 5-wire mode | 100Hz to 5kHz | |

2-28Vrms | 50Hz-10kHz | up to 19.8Vrms | 50Hz-10kHz | |

Using a different device to measure position or velocity? Check out some of these boards:

- Quadrate encoder – QUAD-604

- SSI encoder-SL-514

- Synchro/Resolver – AI-256

- Hall-effect/Variable reluctance – VR-608

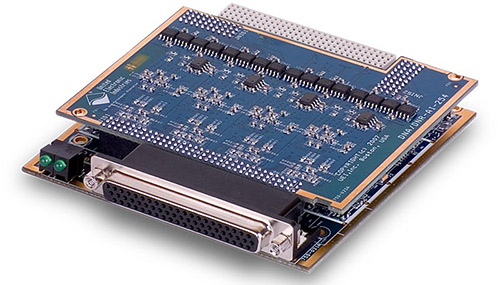

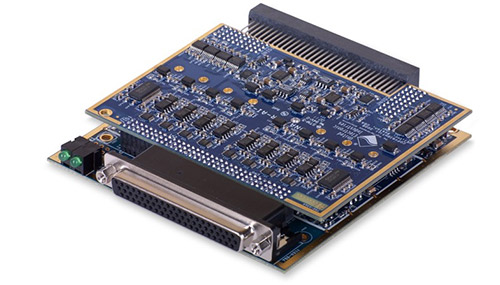

| The DNx-AI-254 is a four channel LVDT/RVDT input and output simulation boards for UEI's powerful data acquisition and control chassis. The boards are ideally suited for a wide variety of rotational and linear motion measurements in many industries. The boards also offer a unique LVDT/RVDT simulated output capability designed to provide stimulus in avionics test and simulator applications. Each of the four channels on the board may be configured as either an input channel with excitation or as an output/simulator. Click here to learn more. |

| The DNx-AI-256 High Output Drive Synchro/Resolver/LVDT/RVDT board features 2 input / output channels, 16-bit resolution, 3-wire (Synchro) and 4-wire (Resolver) inputs, 4, 5 and 6-wire LVDT/RVDT support, reference output per channel, 5 to 18 Vrms programmable reference, 50 Hz to 10 kHz, and up to 2.4 VA without external buffer. Click here to learn more. |

LVDT/RVDT Tutorial Videos

Interpreting Data From an Aircraft Throttle Using UEI RVDT Synchro I/O Board

Our lead design engineer demonstrates how he can use a four channel LVDT/RVDT I/O board to read the output from an aircraft thrust level and display the changes in real-time via onboard web server. The board also outputs the pulse width modulation signal to control lamps.

LVDT/RVDT Master Class

LVDTs and RVDTs are robust, theoretically infinitely precise positioning devices. These devices are used everywhere from the thrust levers on fighter jets to cryogenics labs. The UEI Applications Group will cover how these devices work, and how to interface with them using our DNx-AI-254 LVDT/RVDT Interface Board. We will also take this opportunity to demonstrate both the Low-Level C-API and the High-Level Framework API. Whether it is C, C++, Python, or a wide array of .NET languages, UEI is flexible on the software side, and rugged on the hardware side.

Related Applications

UEI has a wide variety of solutions for your defense and aerospace applications. Please click on the below to learn more.

|  |  |  |